The Critical Role of Tooling Maintenance in Ensuring Encapsulation Quality

Within the pharmaceutical or nutraceutical industry, the reliability and precision of encapsulation processes play a pivotal role in ensuring the efficacy and safety of medications. Amidst this, tooling maintenance emerges as the cornerstone in safeguarding the integrity of encapsulation operations. A robust tooling maintenance program stands as the foremost defense against encapsulation issues, making it imperative to constantly monitor and address various segments of encapsulation tooling for bore imperfections and other concerns.

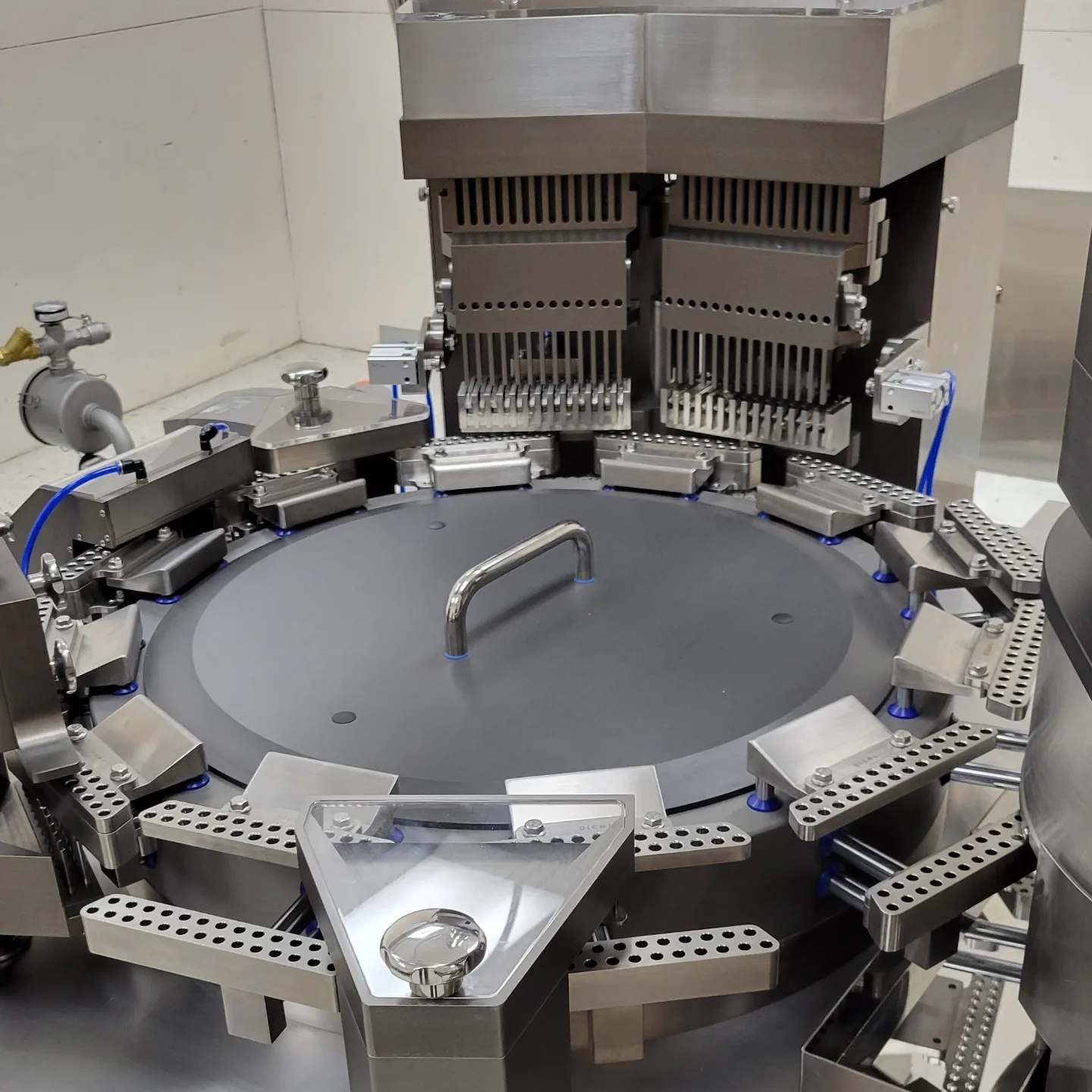

Encapsulation tooling encompasses various components, each integral to the seamless filling and closure of capsules. These segments demand vigilant inspection and maintenance to prevent issues such as separation problems or closure inconsistencies that could compromise capsule quality. Among these crucial segments are:

1. Segment bore Imperfections: Constant checking for bore imperfections within the encapsulation tooling is paramount. Imperfections within the segment bores can lead to capsule separation or closure problems, affecting the overall quality of the final product. Ensuring that these bores are smooth and devoid of irregularities helps in maintaining the integrity of the capsules and prevents issues during the filling and closing processes.

2. Capsule Separation and Closure: Imperfections in tooling segments can directly impact capsule separation and closure. A lack of proper maintenance can result in misalignment or inadequate sealing of capsule halves, leading to potential leakage or dosage inconsistencies. This, in turn, jeopardizes capsule quality and compromises the efficacy of the product being produced.

3. Tamping Pins Maintenance: Tamping pins are instrumental in ensuring uniform filling and compression of capsule contents. Keeping these pins straight and in optimal condition is essential to maintaining consistent dosing within each capsule. Any deviation in the alignment or condition of these pins can result in inaccurate dosages and affect the overall quality of the encapsulated product.

4. Dosing Disc Bore Maintenance: The bores in the dosing disc must maintain a smooth surface to prevent issues such as metal shavings contaminating the fill material. Regular inspection and maintenance of these bores are critical to ensuring accurate and consistent dosage within each capsule.

Failure to address these maintenance aspects not only affects capsule quality but also poses potential attack issues within pharmaceutical manufacturing. Capsule separation, compromised capsule quality, or closure problems can introduce vulnerabilities in the manufacturing process, risking product integrity and consumer safety.

Furthermore, the maintenance of encapsulation tooling is imperative for regulatory compliance and adherence to stringent quality standards. Pharmaceutical and nutraceutical manufacturers must adhere to rigorous regulations to maintain the highest standards of quality, and proper tooling maintenance is a fundamental component of meeting these requirements.

In conclusion, the significance of a comprehensive tooling maintenance program in encapsulation cannot be overstated. It serves as the primary defense against a myriad of issues that could compromise capsule quality, dosage accuracy, and overall production integrity. By ensuring the consistent upkeep of critical tooling segments and components, pharmaceutical and nutraceutical manufacturers can uphold the highest standards of quality and efficacy in their encapsulated products.