KLS-225 Capsule Filling Machines

Home > KLS-225

KLS-225 Capsule Filling Machine

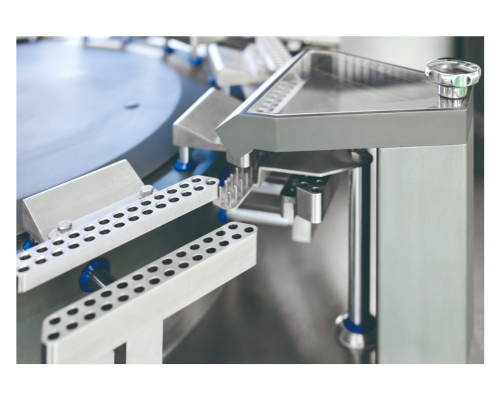

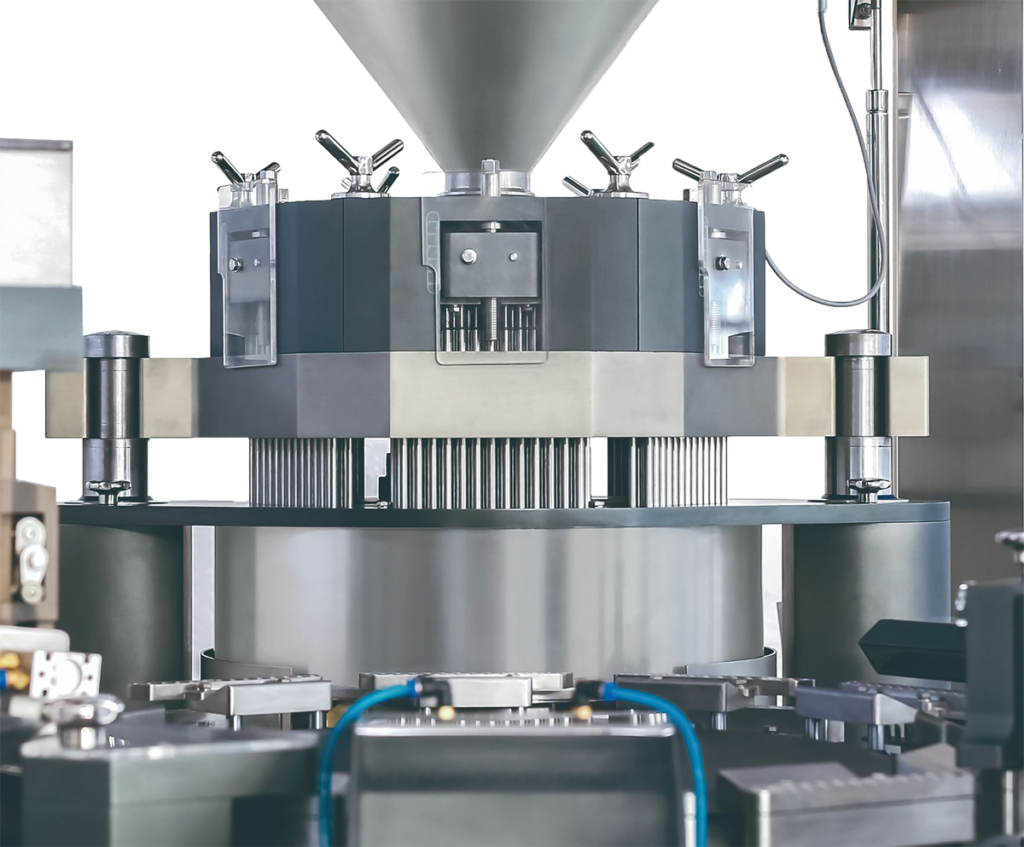

The KLS-225 Capsule Filling Machine is a high-speed, tamping-style capsule filler with a maximum production rate of 225,000 capsules per hour. The KLS-225 is equipped with state-of-the-art safety features, time-saving mechanical designs and an easy-to-use control system.

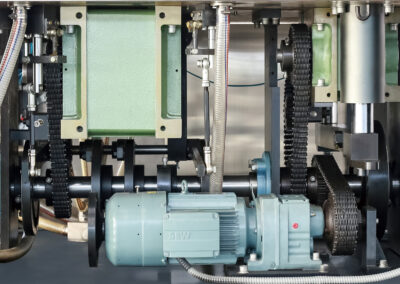

The main motor, indexing drives and vacuum pump are robust, precise and durable. Auxiliary equipment is available to help with automatic powder loading, automatic empty capsule loading, dust collection and capsule polishing.

KLS-225 Features

Efficient

- Accurate & Consistent Weights

- Fast Change-Overs

- High Yields

- Integrated Auxiliary Equipment

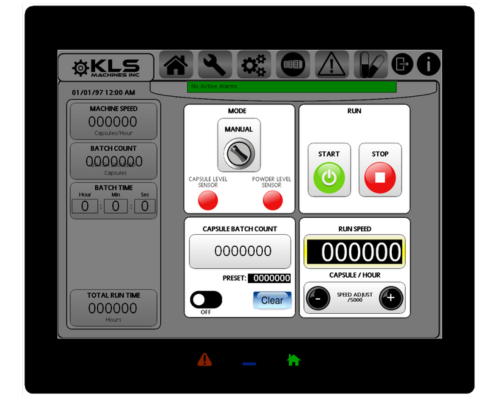

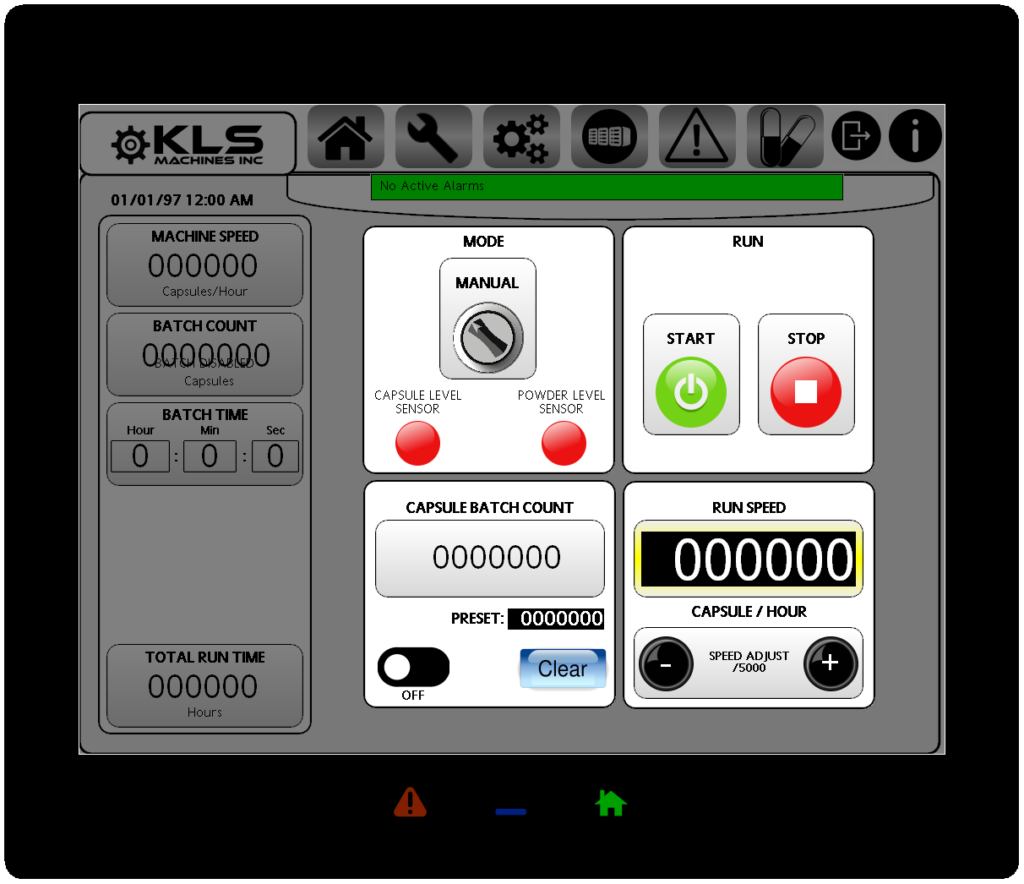

Advanced Control Systems

- Simple and Intuitive 15” Touch Screen

- Easy to Support

- Interlocks on Upper & Lower Doors

- Standard UL-Compliant Panel

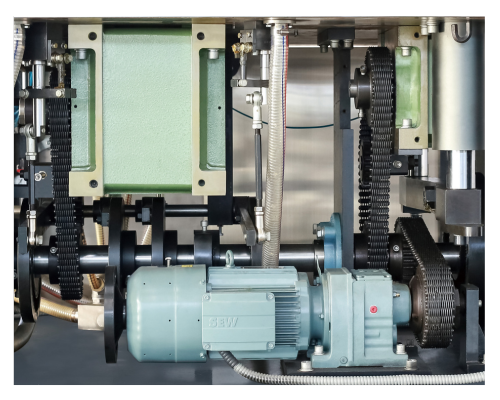

Reliable

- 7,500 lbs

- Steel Base and Frame

- Robust Motors, Drives

- Inverted Silent Tooth-Chains

Elite Customer Support

- On-site Service and Training

- Remote Troubleshooting

- Extensive Spare Parts Inventory

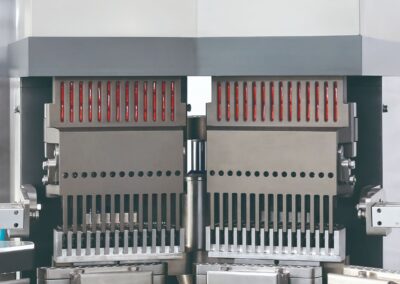

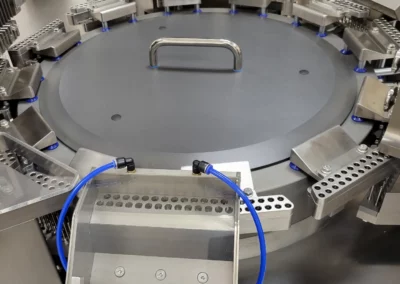

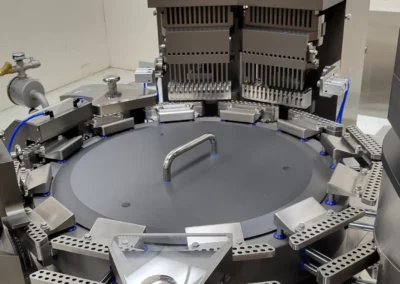

Durable & Precise

Precise tolerances and rugged components are key to ensuring that manufacturers consistently hit accurate weights and high yields.

With a solid steel frame and base construction and a total weight of 7,500 lbs, the KLS-225 runs smooth and efficient at high speeds with tough to run products.

Easy To Use Control System

Integrated Auxiliary Equipment

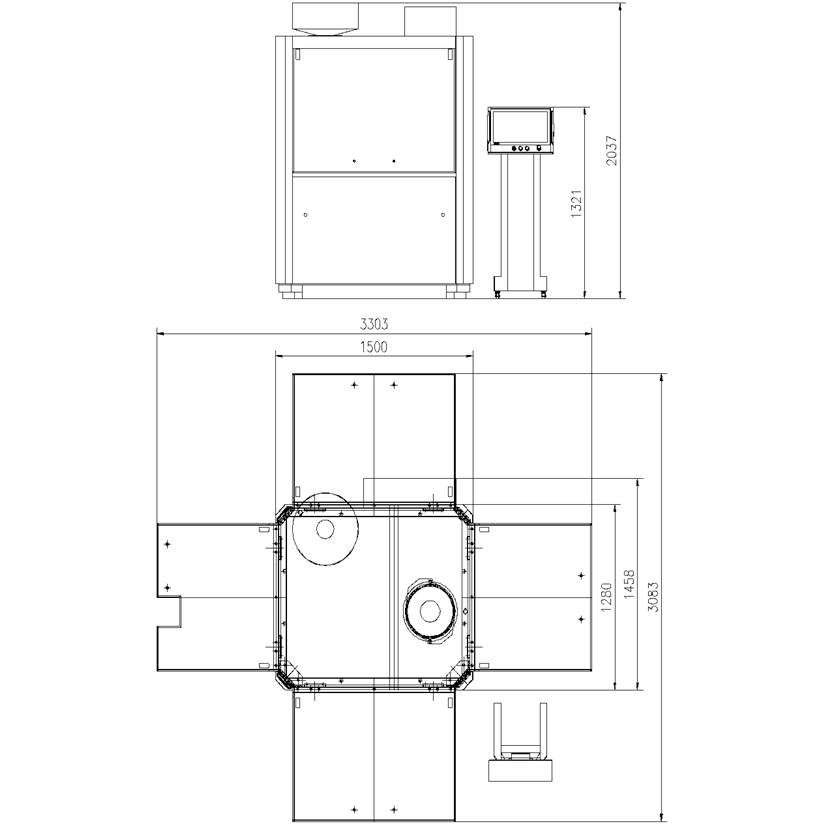

Specifications

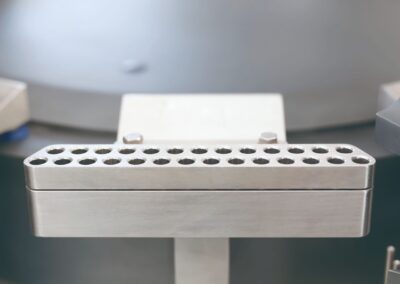

Capsules per Segment: 27

Max Speed: 140 rpm

Capsule Range: 00EL – 4

Dimensions: 6’ × 5’ × 7’

Weight: 7,500 lbs

Idle Noise: <75 dB(A)

Room Temperature: 70 F +/-50 F

Room Humidity: 50% +/-5%

Required Power: 460V 60HZ 3PH 20A

Required Air Pressure: 100 psi